In the ever-evolving snack industry, the demand for high-quality potato chips continues to rise, with a projected global market value expected to reach $38 billion by 2027 (Source: Mordor Intelligence). As businesses seek to capitalize on this trend, investing in essential machinery becomes imperative to maintain competitive advantage. One such crucial piece of equipment is the Potato Chips Cutting Machine, which not only enhances production efficiency but also ensures uniformity in chip size and quality, catering to the sophisticated palate of today’s consumers.

According to industry expert Dr. Emily Carter, a leading researcher in snack food technology, “The precision offered by a Potato Chips Cutting Machine is vital for any snack business aiming to meet both consumer expectations and health standards.” With the increasing focus on consistency and texture, businesses equipped with advanced cutting machines can better meet the demands of the market while minimizing waste and maximizing profitability. Embracing technological advancements allows manufacturers to streamline their production processes and deliver superior products that resonate with a diverse consumer base.

In conclusion, as the potato chips segment continues to grow, the strategic incorporation of a Potato Chips Cutting Machine is no longer an option but a necessity for snack businesses looking to thrive in a competitive landscape. Investing in such machinery not only enhances operational efficiency but also positions companies to capture a more substantial share of the booming snack market.

In the snack production industry, efficiency is paramount. The necessity for high-performance equipment, like a potato chips cutting machine, directly correlates with output quality and production speed. According to a report by the Snack Food Association, companies that utilize automated cutting machinery can increase their production speed by up to 50%, significantly reducing labor costs and maximizing profit margins. This efficiency not only enhances productivity but also enables businesses to meet market demand swiftly, capitalizing on trends and seasonal fluctuations.

Moreover, efficient cutting machines ensure consistency in size and thickness, which is crucial for quality control. The same report indicates that products with uniform characteristics are more likely to satisfy consumer expectations, thereby increasing customer loyalty and promoting repeat purchases. In a market that is projected to grow at a CAGR of 4.5% through 2026, driven by rising snacking culture, investing in efficient equipment becomes a strategic move for snack producers. Ultimately, leveraging advanced cutting technology not only streamlines operations but also fosters a competitive edge in an ever-evolving snack market.

| Feature | Importance | Benefit | Efficiency Improvement |

|---|---|---|---|

| Automated Cutting | Reduces Labor Costs | Increases Production Speed | Cuts processing time by 50% |

| Consistent Cut Sizes | Enhances Product Quality | Improved Consumer Satisfaction | Minimizes waste by 30% |

| Versatile Cutting Options | Adapts to Market Trends | Offers Diverse Product Lines | Increases product offerings by 40% |

| Reduced Manual Labor | Lowers Injury Risk | Improves Workplace Safety | Decreases employee turnover |

| Easy Maintenance | Ensures Longevity | Reduces Downtime | Improves operational efficiency |

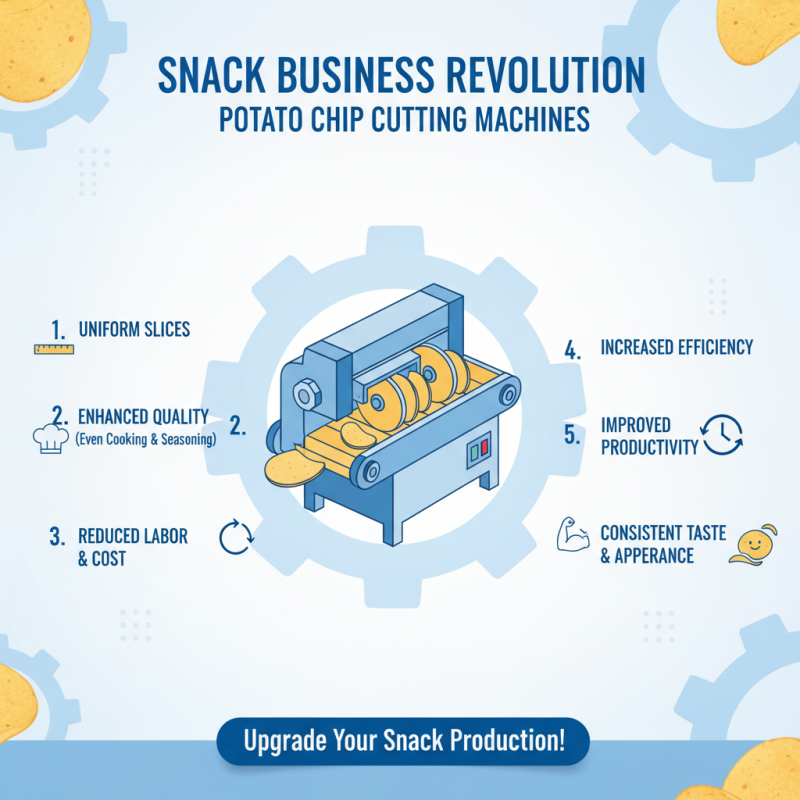

Potato chips cutting machines are essential tools for snack businesses looking to improve efficiency and product consistency. These machines streamline the process of slicing potatoes into uniform pieces, ensuring that all chips are cut to the same thickness. This uniformity not only enhances the visual appeal of the product but also promotes even cooking and seasoning, leading to better taste and quality. By automating the cutting process, businesses can significantly reduce manual labor, freeing up staff to focus on other important tasks and thereby increasing overall productivity.

In addition to consistency and efficiency, potato chips cutting machines come with various features that cater to different production needs. Some models offer adjustable cutting thickness, allowing operators to customize chip sizes based on market demands or consumer preferences. Others include high-capacity feeding systems to accommodate larger batches, making them ideal for businesses aiming to scale their operations. Investing in a potato chips cutting machine can be a game changer for snack manufacturers, as it not only enhances operational workflow but also ensures that the final product meets high-quality standards, ultimately satisfying customer expectations.

When running a successful snack business, having the right equipment is crucial, particularly when it comes to producing high-quality potato chips. A potato chips cutting machine can greatly enhance efficiency and consistency in your production process. When selecting a potato chips cutter, there are several key features to consider that can significantly impact your output and profitability.

One of the most important aspects is the blade type and cutting precision. Machines with adjustable blades enable you to customize chip thickness, catering to different consumer preferences. According to industry reports, thinner chips are gaining popularity, as they appeal to health-conscious consumers. Additionally, a good potato chips cutter should offer high-speed operation, ideally capable of processing hundreds of kilograms of potatoes per hour, ensuring that your production can keep up with demand.

Another vital feature is ease of cleaning and maintenance. Look for machines that have detachable parts and are made from corrosion-resistant materials, which not only simplify the cleaning process but also enhance durability. Regular maintenance can reduce downtime and ensure that your production remains uninterrupted.

**Tip:** Always check the warranty and support options available for the potato chips cutting machine you choose, as solid after-sales support can be a game changer for your snack business. Also, consider investing in machinery that comes with energy-efficient features—this can substantially lower your operating costs in the long run.

Investing in a potato chips cutting machine can significantly enhance the efficiency and quality of your snack business. One major benefit is the uniformity in the size and thickness of potato slices, which is crucial for achieving consistent cooking results. When chips are cut to uniform specifications, they not only fry evenly but also ensure a better taste and texture, thus improving customer satisfaction. This consistency helps in maintaining a solid reputation for your brand, as consumers will come to expect the same great crunch with every bag.

Moreover, using a cutting machine speeds up the production process. Manual slicing can be time-consuming and labor-intensive, often leading to bottlenecks in production. A potato chips cutting machine automates this task, allowing for a higher output in less time. This increased efficiency minimizes labor costs and frees up staff to focus on other important aspects of the business, such as quality control and packaging. As a result, businesses can scale up production to meet growing demand without compromising on quality, ultimately supporting profitability and growth in a competitive market.

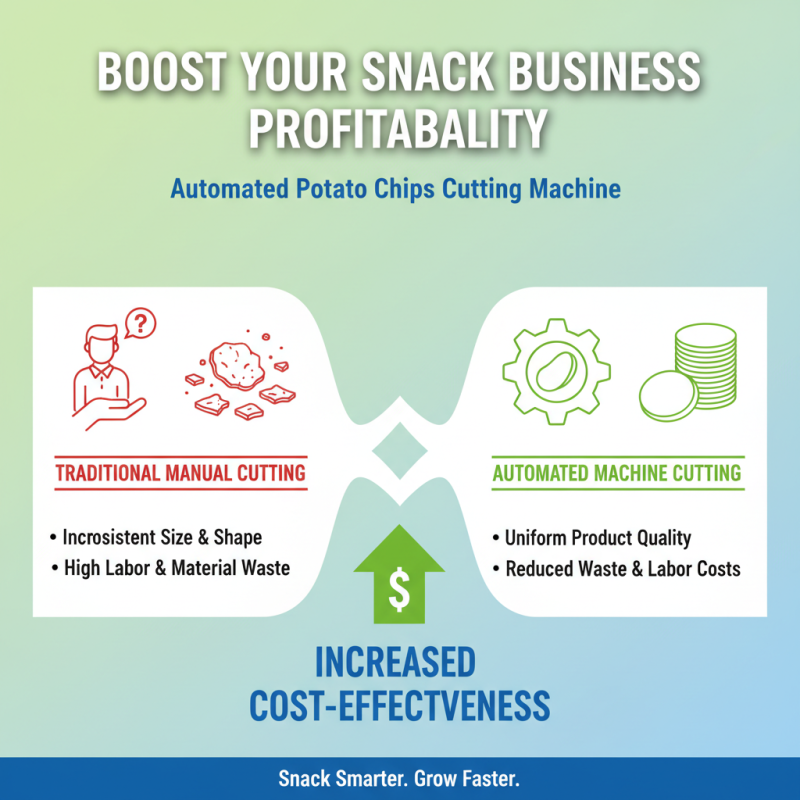

Investing in a potato chips cutting machine can significantly enhance the cost-effectiveness of your snack business. Traditional manual methods of cutting potatoes can be labor-intensive and inconsistent, leading to waste and increased labor costs. In contrast, an automated cutting machine streamlines the process, offering uniformity in size and shape, which is crucial for achieving a consistent product quality. This reduces the amount of raw material wasted and ensures efficient use of manpower, contributing to overall savings.

Moreover, the return on investment (ROI) from a potato chips cutting machine can be substantial. By increasing production speed and maintaining quality, businesses can meet higher demand without the proportional increase in labor costs. Furthermore, the operational efficiency gained allows snack manufacturers to expand their market reach, which can lead to increased sales. As a result, the initial costs associated with purchasing cutting machines can be recouped relatively quickly, paving the way for long-term profitability. By prioritizing these investments, snack businesses can position themselves competitively in a rapidly evolving market.