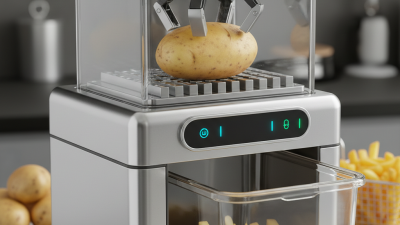

Crinkle Fries Cutting Machine is a delightful kitchen tool. It transforms ordinary potatoes into fun, crinkly fries. This machine offers a unique twist to the traditional fry. The cutting process is simple yet fascinating.

Using sharp blades, it carves wavy shapes into the potatoes. Each crinkle adds texture and crunch. Fry lovers adore this special style. Restaurants use these machines to stand out. Home cooks enjoy experimenting with them.

However, mastering the machine can be tricky. Some may struggle to achieve uniform cuts. It's important to adjust settings for different potato types. Practice is key to getting it right. With patience, cooks can create perfect crinkle fries every time.

Crinkle fries cutting machines are specialized equipment designed to create the popular crinkle-cut fries. These machines can slice potatoes into wavy shapes, enhancing both presentation and texture. The unique design allows for better frying, resulting in a crispier exterior and fluffy interior. According to industry reports, the global market for potato processing equipment is projected to reach $7 billion by 2025, indicating a growing demand for efficient food preparation tools.

The primary purpose of these machines is to streamline the cutting process. Manual cutting can be time-consuming and inconsistent. A crinkle fries cutting machine ensures uniformity, which is crucial in commercial settings. Restaurants and food manufacturers benefit from the speed and efficiency of these machines. In fact, the efficiency rate can improve production by up to 30%, allowing quick service during peak hours. However, it's important for users to regularly maintain these machines. Neglect can lead to uneven cuts and potential breakdowns, ultimately affecting output.

Despite their advantages, not all operations may require such specialized equipment. Smaller eateries might find them cost-prohibitive. Moreover, the reliance on machines might reduce the artisanal touch of hand-cut fries. Reflection on these aspects is vital for business owners choosing the right tools for their kitchens.

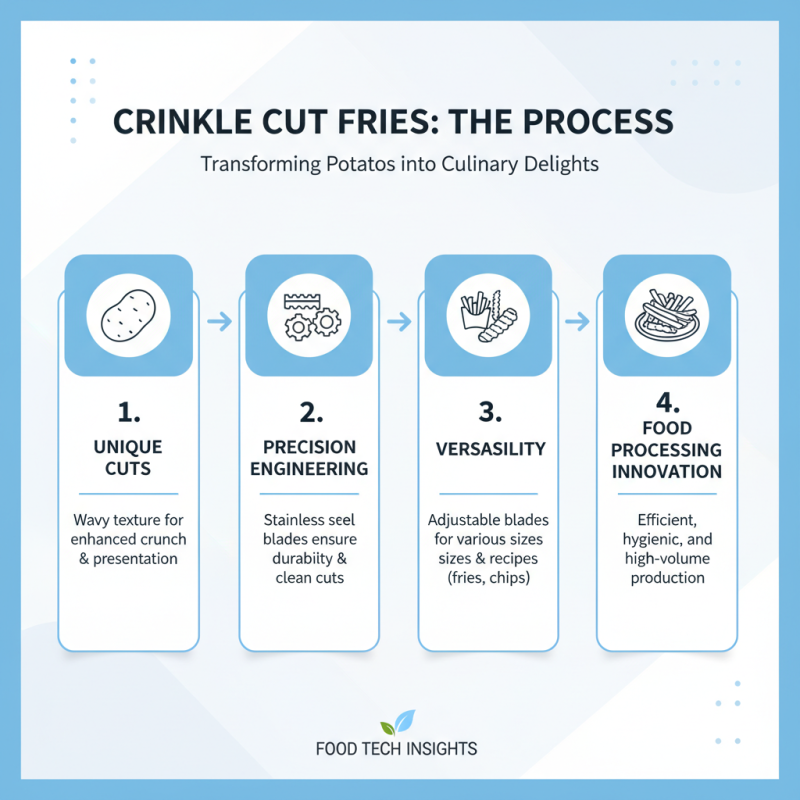

Crinkle fries cutting machines are specialized tools designed to create perfectly crinkled potato fries. They use precision blades that cut potatoes into wavy shapes. This unique cut increases the fries' surface area, allowing for a crispier texture when cooked. Plus, they can create consistent shapes, making them ideal for food service businesses.

Key components of these machines include sharp stainless-steel blades and a sturdy frame. The blades are the heart of the cutter, shaping the fries efficiently. The frame holds everything together, ensuring stability during operation. Advanced models may also feature adjustable settings for different thicknesses.

Tip: Always ensure blades are sharp before use. Dull blades can lead to uneven cuts. Cleaning the machine regularly maintains performance and safety.

Despite their advantages, some machines can be bulky. If space is limited, choose a compact model. Training staff to operate these machines effectively is essential. This reduces waste and promotes consistency in fry quality. Balancing efficiency with operator skill is crucial for best results.

Crinkle fries cutting machines are important in food processing. They create unique, wavy cuts, which enhance texture and presentation. The design often includes stainless steel blades, ensuring durability. These blades can cut potatoes into various sizes, creating versatility for different recipes.

The operational process is straightforward. Potatoes are fed into the machine, which uses a series of blades to slice them into crinkle shapes. Some reports indicate that these machines can process up to 1,000 pounds of potatoes per hour. This efficiency is vital for high-demand restaurants and fast-food establishments. Proper maintenance is crucial, as worn-out blades can affect cut quality.

Despite their efficiency, not every machine delivers perfect results. Misalignment may lead to uneven cuts. Operators must be trained to ensure proper setup. Regular inspections could help prevent issues. The technology continues to evolve, with newer models featuring adjustable settings for different thicknesses. Balancing efficiency and quality remains a challenge for manufacturers. Each crinkle fry must be visually appealing and tasty.

Crinkle fries have become a popular snack in the food industry. Their unique shape and texture make them appealing to consumers. The demand for crinkle fries is growing rapidly. This trend reflects changing preferences toward fun and visually stimulating food. Restaurants and snack vendors are increasingly incorporating crinkle fries into their menus.

The versatility of crinkle fries plays a crucial role in their popularity. They work well with various toppings and seasonings. This makes them an exciting option for customers. Not only are they delicious, but their fun shape enhances the overall eating experience. In fast-casual dining, crinkle fries are becoming a staple. They often accompany sandwiches, burgers, or as a standalone snack.

Despite the growing popularity, some challenges remain. Not all establishments can consistently produce high-quality crinkle fries. This can lead to customer dissatisfaction. Moreover, sourcing the right equipment for cutting potatoes into crinkle shapes is not always straightforward. Many businesses must consider the costs and space needed for a crinkle fries cutting machine. It’s essential to evaluate these aspects before jumping into this trend.

Crinkle fries cutting machines are essential in modern food production. They efficiently create unique crinkle shapes from potatoes. This process enhances the aesthetic appeal, making fries more attractive to customers. The texture of crinkle fries also holds sauces and seasonings better.

Using crinkle fries cutting machines offers various benefits. Firstly, they save time. Faster preparation allows for greater output. This is crucial during busy hours. Additionally, these machines reduce waste. They ensure that more potato is utilized, maximizing profit margins. However, operators need to be trained properly. Misuse can lead to inconsistent results.

Tips: Keep the cutting blades sharp. Dull blades can affect the quality of fries. Regular cleaning is also necessary. Maintain hygiene to avoid contamination issues. Remember, sometimes imperfections can add to the charm. Perfect cuts are not always the goal. Embrace the unique shapes that arise during production. This can lead to customer satisfaction and enjoyment.

| Feature | Description | Benefits |

|---|---|---|

| Cutting Precision | The machine uses specialized blades to cut potatoes into crinkle shapes. | Ensures uniformity in size for even cooking. |

| Production Speed | Designed for high throughput, cutting large quantities of potatoes quickly. | Increases operational efficiency, meeting high demand. |

| Ease of Use | User-friendly controls for easy operation and maintenance. | Reduces training time for staff and minimizes errors. |

| Versatility | Can cut various vegetables into crinkle shapes, not just potatoes. | Expands menu options for food establishments. |

| Durability | Made from high-quality materials designed to withstand heavy use. | Long-lasting equipment reduces the need for frequent replacements. |