Selecting the right Potato Blanching Machine is vital for the success of your potato processing business. Expert John McKenzie, a leader in the food processing industry, emphasizes, "A good blanching machine can make all the difference in quality." The right machine enhances the flavor and appearance of your final product.

When considering a Potato Blanching Machine, think about capacity and efficiency. Machines vary widely in size and output, affecting your production rate. Details matter. A machine’s temperature control can affect the blanching quality. Precision is key; overcooked potatoes lose texture and flavor.

Purchasing a blanching machine is an investment. Evaluate your options carefully. Some machines may not meet your business demands. Research is crucial. A wrong choice can lead to wasted resources and time. By making informed decisions, you can enhance your production process and ensure better quality products for your customers.

Potato blanching is a crucial step in food processing. It helps to preserve flavor, color, and nutritional value. The process involves briefly boiling potatoes before cooling them rapidly. This technique also prepares potatoes for freezing or frying.

When selecting a potato blanching machine, consider its efficiency and capacity. Look for one that fits your production needs. Remember, a machine that is too small may lead to bottlenecks. A large machine can waste energy and water.

**Tip:** Always assess the energy consumption of the machine. An efficient model can save money over time.

Another essential factor is ease of use. Complex machines may require extensive training, which can slow down production. Simpler designs are often more user-friendly. They need less maintenance too, which is a plus.

**Tip:** Read reviews from other users. Their feedback can highlight potential issues with usability or performance.

Being aware of these aspects can significantly impact your business. Blanching not only affects the quality of your end product but also influences your overall efficiency. Investing in the right machine can make all the difference.

When selecting a potato blanching machine, key features can significantly affect productivity and quality. One essential factor is the blanching time and temperature. According to industry reports, effective blanching requires precise temperature control. This ensures optimal enzyme deactivation. A typical blanching time ranges from 3 to 10 minutes, depending on the potato variety. If the time is too short, it may not deactivate enzymes effectively; too long, and the potatoes become mushy.

Another important feature is the machine's capacity. Businesses need to match equipment size with their production volume. A study by the Food Processing Industry Association reveals that machines can handle anywhere from 200 to 2,000 kilograms of potatoes per hour. Choosing a machine too small can lead to bottlenecks, while an oversized machine might lead to higher costs than necessary.

Ease of cleaning is also crucial. Operators must remove residual starch and other impurities regularly. If the design does not facilitate easy cleaning, residues can accumulate. This might affect the quality of future batches. Moreover, consider energy efficiency. Machines that consume more power increase operational costs. Many businesses need to balance efficiency with production quality. Identifying these areas helps in making a thoughtful decision.

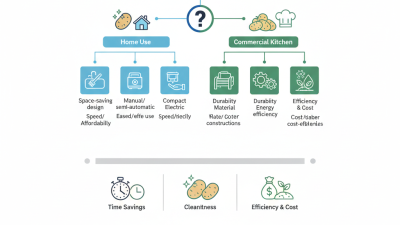

When selecting a potato blanching machine for your business, understanding available types can simplify your decision-making. There are primarily two common types: batch blanchenrs and continuous blanchers. Batch blanchers process small quantities at a time. They are ideal for businesses with lower volume needs. These machines require manual operation and can be slower. However, they offer more control over the blanching process.

On the other hand, continuous blanchers are designed for larger operations. They handle high volumes with efficiency. These machines operate automatically, saving time and labor costs. You can achieve consistent temperature and timing, ensuring uniform results. However, they often require a higher initial investment.

Another option is water blanchers versus steam blanchers. Water blanchers immerse potatoes in boiling water. This method can alter the taste slightly. Steam blanchers, in contrast, retain more flavor and nutrients. Each type has its pros and cons. It’s essential to evaluate your production capacity and goals. Reflect on your business needs before making a choice.

When choosing a potato blanching machine, it's crucial to evaluate your business needs.

Consider the scale of your operations. Are you processing small batches or

large volumes? A high-capacity machine may seem appealing, but

only if it fits your production plan. There’s often a trade-off between speed and energy

consumption. A machine that is too large might waste resources.

Next, think about your space. Some machines require extensive floor space. Ensure

you have room for the equipment and safe access for workers. Product consistency is vital too.

Consider how different machines perform with various potato types. Blanching times should yield

uniform results to maintain quality.

Also, reflect on your budget. Higher upfront costs

might not always translate to better efficiency. Examine the long-term costs associated with different

machines. Will they require frequent repairs? Investing in a cheaper model can lead to higher expenses

over time. Take the time to research options thoroughly. Don't rush the decision; this choice impacts

production for years.

When selecting a potato blanching machine, budgeting is crucial. Understand your financial limits. Research equipment costs can guide you. Consider both purchase and installation expenses. Some machines require significant upfront investment. This can affect your cash flow. Explore options for financing or leasing as alternative solutions.

Analyzing long-term costs is essential. Think about maintenance and operational expenses. Regular upkeep can add to the overall investment. Assess the energy consumption of different machines. An energy-efficient machine may save money over time. Don't forget to factor in the cost of labor. Some machines require skilled operators, which could influence your budget.

It's important to reflect on potential overestimations. Sometimes, believing that high-priced equipment guarantees quality can lead to disappointment. Assess the features you truly need versus luxurious, unneeded extras. Balancing cost and efficiency is tricky. Reassess your priorities as you research. It’s an ongoing process requiring flexibility and careful thought.