Choosing the right French Fry Cutter Commercial for your business can be challenging. There are many options available, and each has unique features. You want a cutter that meets your needs and improves efficiency.

A high-quality French Fry Cutter Commercial should offer precision and speed. Look for a model with durable blades that can handle high volumes. Ease of use is also crucial. If your staff struggles with it, you may face delays.

Remember to consider space limitations in your kitchen. Some models are larger and take up more space. Reflect on your workflow and the training needed. It’s important to invest wisely to avoid regrets later.

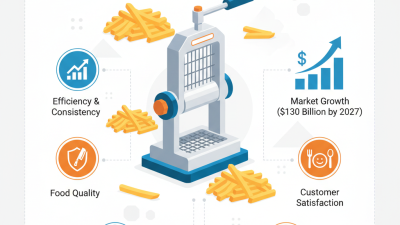

Understanding the importance of a high-quality French fry cutter is essential for any food business. A reliable cutter not only saves time but also ensures consistency in size and texture. According to industry reports, businesses lose up to 30% in labor costs due to inefficient kitchen tools. A commercial-grade French fry cutter can streamline operations and boost profits.

Tip: When selecting a cutter, consider the volume of fries you will serve daily. A heavy-duty model might be necessary for high-traffic establishments. Efficiency should be a priority, as time wasted means money lost.

Moreover, the precision offered by a quality cutter leads to uniform fries. Consistent fry sizes cook evenly, which enhances customer satisfaction. Research indicates that mismatched fry sizes can result in poor dining experiences. Remember, not all cutters deliver the same quality.

Tip: Look for features like adjustable blade sizes. This ensures you can offer varied fry styles. Think about your menu. Will you serve steak fries or crinkle cuts? Matching your cutter to your offerings is key. A good French fry cutter is not just a tool; it’s an investment in your business that can yield significant returns.

This chart provides a comparison of essential features to consider when selecting a high-quality commercial French fry cutter for your business needs. Each feature is rated on a scale of 1 to 100, with higher scores indicating better performance.

When selecting a commercial French fry cutter, consider the volume of potatoes your business processes daily. A report by IBISWorld indicates that the fast-food industry in the U.S. generates $223 billion annually. This highlights the demand for efficient kitchen equipment. A quality cutter can be the backbone of a busy kitchen.

Blade size is crucial. A 1/4-inch cut may be ideal for thicker fries, while a thinner blade creates a crispy finish. Evaluate how much labor the cutter saves. Manual models can require significant effort for large quantities. An automated cutter can improve efficiency but may come with higher costs.

Material durability is another factor. Stainless steel cutters resist rust and wear. However, cheaper plastic options can degrade over time. Some may require frequent replacement. Lastly, consider ease of cleaning. A complicated design may hinder quick maintenance, leading to longer downtime. Reflect on what features best fit your operation, balancing cost against expected performance.

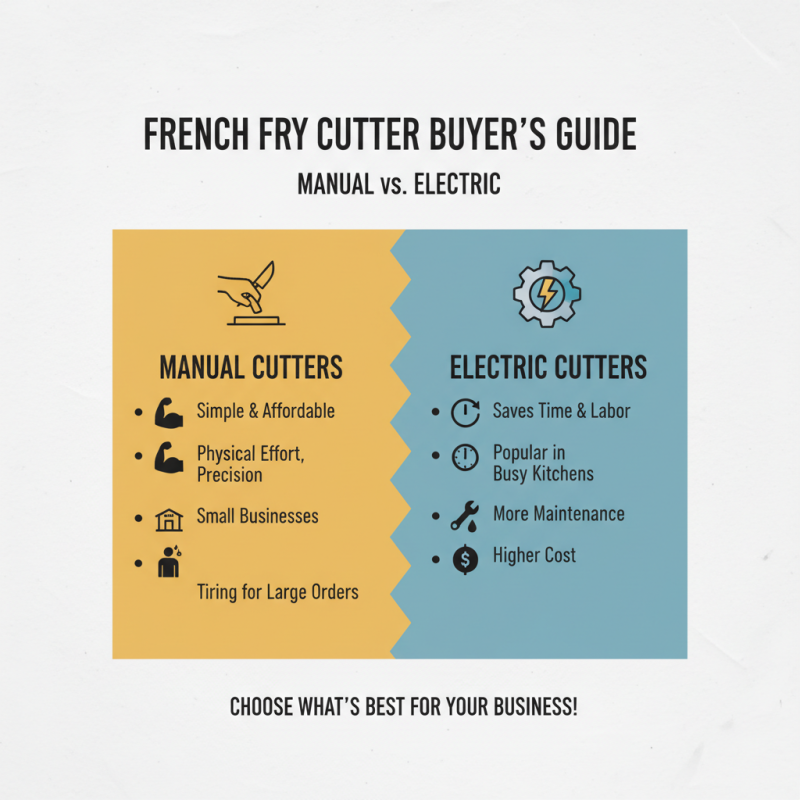

When selecting a French fry cutter, understanding the different types available is crucial for your business. Manual cutters are simple and affordable. They often require physical effort but offer precision. These are suitable for small establishments but can be tiring for large orders. Electric cutters are a popular choice among busy kitchens. They save time and labor. However, they may require more maintenance and come at a higher cost.

Consider the size and volume of your potato preparation. Some cutters can handle bulk orders faster, while others might excel in specialty cuts. For instance, crinkle-cutters add a unique presentation but may not be as efficient during peak hours. Think about the ease of cleaning, too. Complex designs can lead to food residue build-up, which might be a hassle.

Each business has distinct needs. Different kitchens may require different features. Reflect on your workflow. Do you need speed or variety? Are you prepared to invest in a specific type? Decide what aligns best with your daily operations. It’s okay to be unsure. Testing out a few options can provide clarity.

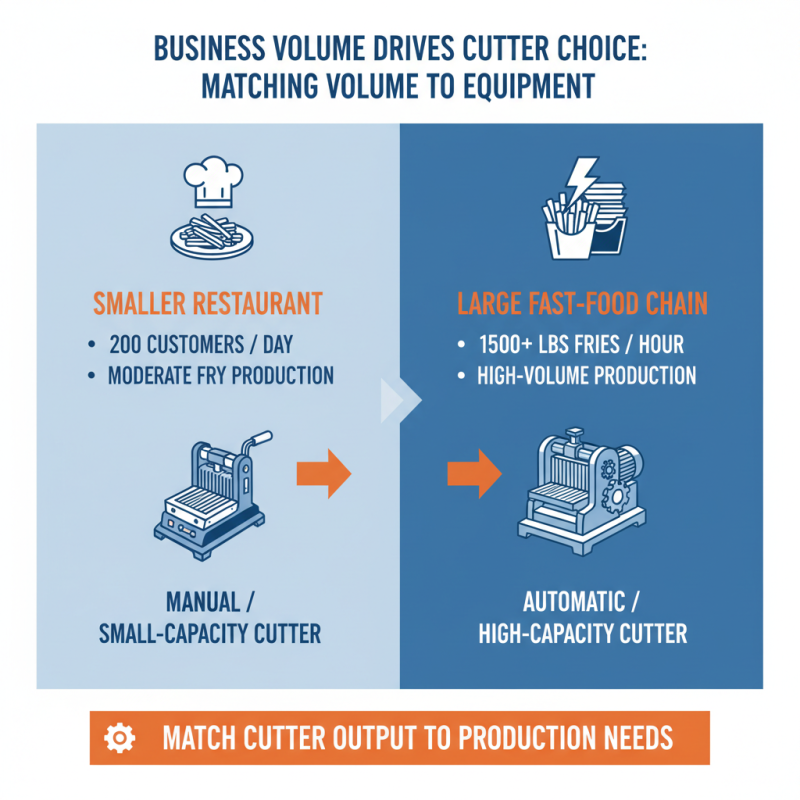

When evaluating your business volume, consider its direct impact on your French fry cutter selection. A restaurant serving 200 customers daily requires different equipment than a fast-food chain processing over 1,500 fries each hour. Reports indicate that businesses must match the cutter's output to their production needs. A high-capacity cutter may seem beneficial, but it could be excessive for smaller operations.

It's crucial to analyze your volume trends. During peak times, demand surges, requiring more efficient tools. You might find yourself frequently cleaning the cutter, which drains time. A cutter that fits your everyday needs should balance efficiency and ease of maintenance. Data shows that over 50% of restaurant owners prioritize speed but discount the need for regular upkeep.

Reflecting on your actual fry orders is vital. If your business experiences fluctuating demands, flexibility in cutter size and capacity is key. Investing in a cutter that is consistently too small can lead to delays. Conversely, an oversized cutter can lead to waste and higher costs. Finding a sweet spot for your operation ensures optimal performance without unnecessary expenditure.

When considering a commercial French fry cutter, price and value for money are crucial. A recent industry report highlighted that businesses can spend anywhere from $50 to $500 on such equipment. The initial cost may seem daunting, but durability and efficiency are key. A quality cutter can yield thousands of fries a day, making that investment worthwhile.

Another factor is maintenance costs. According to a survey, around 25% of operators face unexpected repair expenses for their fry cutters within the first year. This can erode potential profits. Choosing reliable equipment can minimize these unforeseen costs. Cheaper models may save money upfront but can lead to higher long-term expenses.

Performance is paramount. A cutter’s output is often measured in pounds per hour. High-end models can produce over 100 pounds of fries in an hour, while cheaper options might struggle to reach 50 pounds. This significant difference in productivity can impact service speed during peak hours. Therefore, businesses should weigh the upfront cost against potential revenue generated from faster service.