In the modern culinary world, the demand for homemade and crispy snacks is at an all-time high, making the "Potato Chips Dryer Machine" an essential tool for both home cooks and commercial establishments. According to John Richards, a leading expert in food processing equipment, "Investing in a high-quality Potato Chips Dryer Machine can elevate the quality of your products while maximizing efficiency." With various options available on the market, selecting the right dryer machine can significantly impact not only the taste and texture of the potato chips but also the overall profitability for businesses.

Understanding the features that distinguish high-performing Potato Chips Dryer Machines is crucial for making a wise investment. Whether you're looking to create a delightful snack for family or seeking to launch a new product line, the right machine will ensure consistent results and streamline your cooking process. As the popularity of homemade snacks continues to grow, both individuals and entrepreneurs must carefully assess their needs, budget, and the specific characteristics of the machines they consider, all while keeping quality and efficiency at the forefront of their decision-making process.

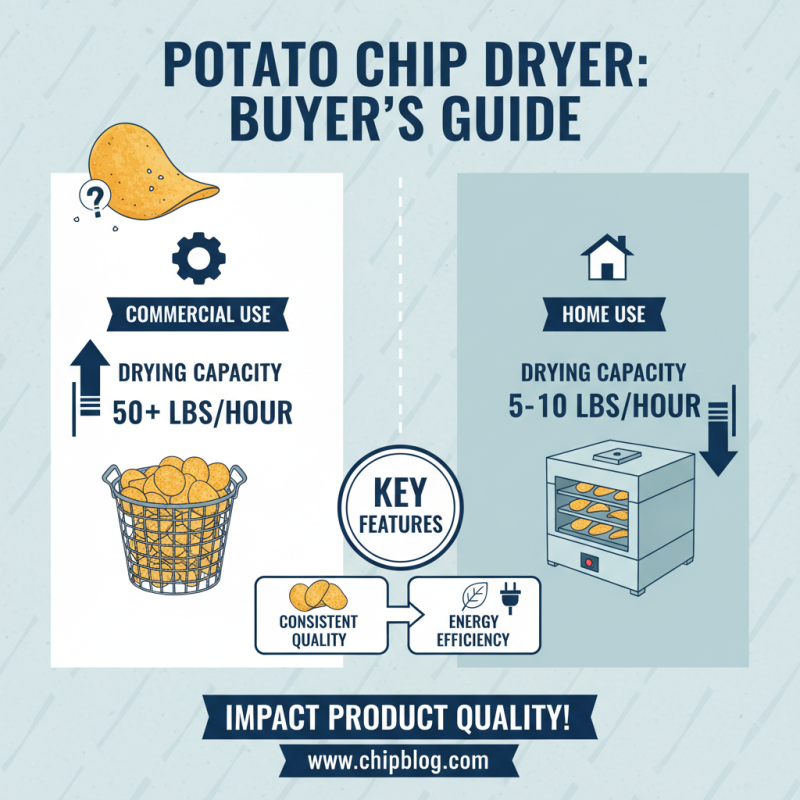

When selecting a potato chips dryer machine, several key factors should be considered to ensure optimal performance for home or business use. Firstly, the capacity of the machine is crucial. For a small household, a dryer with a capacity of 5 to 10 kilograms may suffice, while commercial operations might require larger models that can handle 50 kilograms or more per batch. According to industry reports, the demand for high capacity dryers has increased by approximately 15% over the last year, highlighting the industry's shift towards machines that can accommodate larger quantities efficiently.

Energy consumption is another critical factor. Efficient dryers can significantly reduce operational costs, with energy savings of up to 30% noted in recent studies. Look for machines with variable temperature settings and timers, which allow for customized drying processes tailored to specific chip thickness and moisture content. It’s also advisable to review the drying technology used, such as convection drying versus infrared drying, as each method presents different advantages in terms of speed and quality.

Tips: Always evaluate user reviews and machine specifications before making a purchase. Additionally, consider the ease of cleaning and maintenance, as a well-maintained dryer can extend the lifespan and enhance efficiency. Lastly, don't overlook the availability of spare parts and customer service support, which can be invaluable in ensuring long-term satisfaction with the equipment.

When selecting a potato chips dryer machine, understanding the different types of dryer technologies available is crucial. Two prominent technologies widely adopted in the industry include hot air drying and vacuum drying. According to a 2022 report by the International Journal of Food Science, hot air drying remains the most common method due to its cost-effectiveness and simplicity of operation. In this process, hot air circulates around the potato slices, removing moisture while ensuring a crispy texture. The efficiency of this method can be enhanced by optimizing factors like airflow and temperature, which help achieve up to 90% moisture removal in less than an hour.

On the other hand, vacuum drying offers unique benefits by reducing the drying temperature, thus preserving the flavor and nutritional content of the chips. This technique operates at lower pressures, allowing moisture to evaporate at a faster rate without compromising the product's quality. Industry analyses, such as those published by Food Processing Technology, indicate that vacuum drying can yield chips with superior taste and texture while minimizing the acrylamide formation, a compound of concern in fried snacks. Choosing between these technologies depends on the specific needs of the business or home user, including budget constraints and desired chip quality.

When selecting a potato chips dryer machine, it's crucial to understand the differing requirements between home and commercial applications. Home potato chips dryers are typically compact, designed for personal use, and cater to smaller batches of chips. These machines often emphasize energy efficiency and ease of use, making them ideal for home cooks looking to experiment with their recipes. They feature simpler controls and may utilize convection or air drying methods, allowing users to prepare healthier snacks without the need for excessive oil.

In contrast, commercial potato chips dryers are built to handle larger volumes and provide consistent results at a faster pace. These machines are engineered for efficiency and durability, capable of processing substantial quantities of chips to meet high demand. They often incorporate advanced technology, such as programmable settings and multiple drying modes, to ensure uniformity in texture and flavor. Moreover, commercial dryers tend to have larger capacities and superior build quality, designed to withstand the intense operational demands of a busy kitchen or processing facility. This makes them essential tools for businesses aiming to produce potato chips in bulk while maintaining quality standards.

When selecting a potato chips dryer machine, energy efficiency ratings play a critical role in determining both the operational effectiveness and the long-term costs associated with running the equipment. Machines with high energy efficiency ratings consume less power, which directly translates into lower utility bills. This aspect is particularly important for businesses aiming to maintain profitability without sacrificing production quality. By investing in energy-efficient models, users can not only reduce their environmental footprint but also enhance their bottom line over time.

Moreover, understanding the impact of energy efficiency on operating costs is essential for both home users and businesses. For instance, a machine that uses advanced technology to minimize energy consumption can save considerable money in the long run, even if the initial purchase price is higher. Therefore, it's crucial to analyze the energy ratings and operational specifications before making a choice. Additionally, regular maintenance of the dryer machine can further optimize energy usage, ensuring that it operates at peak efficiency throughout its lifespan. Overall, prioritizing energy efficiency not only benefits financial outcomes but also supports sustainable practices in food processing.

When selecting a potato chips dryer machine for home or business use, there are several key features to consider that can significantly impact the quality of the final product. First, the drying capacity is essential; a machine that can handle at least 50 pounds of raw potatoes per hour is ideal for commercial settings, according to industry standards. This capacity ensures efficiency and meets the demands of higher output required for business operations. For home use, models that accommodate smaller batches, around 5 to 10 pounds, can suffice, balancing convenience and performance.

Another critical feature is the drying method employed by the machine. Convection drying is often favored in high-quality dryers because it circulates hot air uniformly, resulting in consistent moisture removal and crispier chips. A report by the International Journal of Food Science highlights that well-designed convection dryers can reduce moisture content to below 5%, which is crucial for enhancing shelf life and flavor. Additionally, temperature control settings are pivotal; devices that allow precise adjustments between 120°F to 180°F provide flexibility for different types of potatoes and desired chip textures. By focusing on these features, consumers can ensure they choose a potato chips dryer that meets both personal and business needs effectively.