In the world of snack production, achieving the perfect crunch can be challenging. The right equipment makes all the difference. According to industry expert John Smith, “A quality Potato Chips Dryer Machine is essential for crispy snacks.” This statement highlights the importance of selecting the right technology to enhance flavor and texture.

A Potato Chips Dryer Machine not only removes excess moisture but also ensures uniform drying. This technology is vital for maintaining the chips' crispiness. Many manufacturers struggle to find a solution that effectively balances texture and taste. It's not just about drying; it’s about doing it right.

Moreover, efficiency in drying can impact overall production costs. Some machines may promise perfection but fall short in real-world applications. Operators must choose wisely, keeping both quality and budget in mind. The journey to the ideal potato chip is ongoing, and the right dryer can be a game-changer in this quest.

When selecting a potato chips dryer machine, several factors come into play. Think about the capacity you need. A small family may require less space than a commercial kitchen. Medium-sized machines often strike a balance. They can produce enough chips for gatherings without overwhelming your kitchen space.

Next, consider the drying method. Some machines use hot air, while others may rely on oil. Each method affects texture and flavor. Hot air might yield a lighter snack, but oil can create that classic crispiness. Be aware that over-drying can lead to chips that are too crunchy. Finding the right drying time can be a bit of trial and error.

Energy efficiency is another key factor. A machine that consumes too much power can increase your bills. Look for models with energy-saving features. However, sometimes these machines may take longer to dry the chips, leading to increased wait time. Experimentation might be necessary to find the perfect balance between drying time and crunchiness.

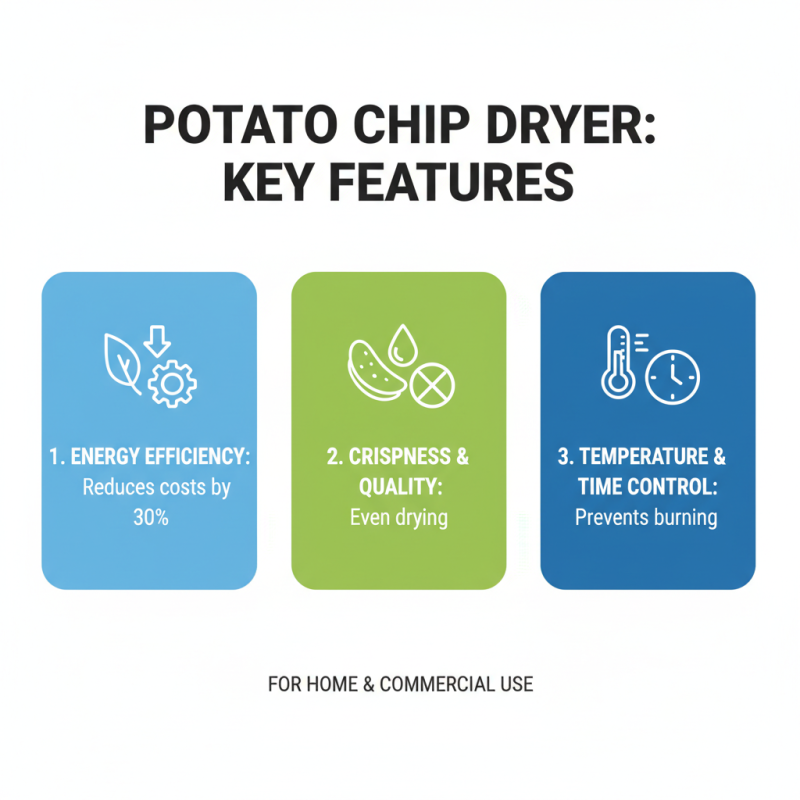

When choosing a potato chips dryer machine, specific features can significantly impact the crispiness and quality of the final product. Energy efficiency is one crucial factor. Machines that use less energy can help keep production costs down. According to recent reports, energy-saving models can reduce costs by 30%. This makes them appealing for both home users and commercial enterprises.

Temperature control is vital for achieving that perfect crunch. A dryer that offers precise temperature settings ensures even drying. Too high a temperature can lead to burnt chips, while too low may leave them soggy. Look for machines that allow you to adjust settings easily.

Tips: Always read user reviews before purchasing a machine. They often provide insights into real-world performance. Additionally, cleaning and maintenance features are essential. A machine that is easy to clean ensures better hygiene and improves its longevity. Remember, a more complicated machine isn’t always better; simplicity often translates to reliability.

When it comes to making perfect potato chips, moisture content is key. The industry standard dictates that the moisture should be around 2-3%. This precise level ensures chips are crispy and flavorful. Too much moisture leaves chips soggy. Too little makes them brittle and crumbly. Achieving this balance can be tricky.

Choosing the right dryer machine is crucial. Look for one that can effectively reduce moisture without cooking the chips. Heat should be evenly distributed. This helps avoid hot spots that can ruin texture. Ventilation is also important. It allows moisture to escape during the drying process.

**Tip:** Regularly check your chips during drying. A minute too long could lead to changes in texture.

Maintaining an ideal temperature ensures consistency. Each batch can vary based on potato size and thickness. Understand that not all chips will come out perfect on the first try. Learn from batches that don’t meet expectations. Adjust variables like drying time and machine settings for better results.

**Tip:** Keep notes on each batch. This will help you refine your technique over time.

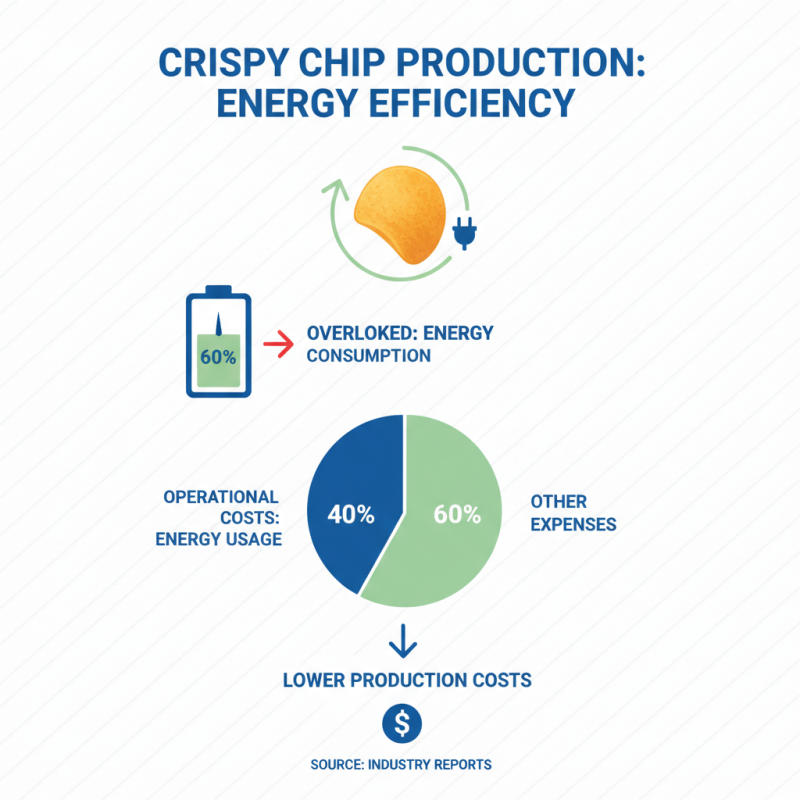

In the pursuit of perfectly crispy potato chips, energy efficiency is often overlooked. Many users focus solely on output quality. However, understanding energy consumption can significantly impact production costs. According to industry reports, energy usage in food processing accounts for nearly 40% of total operational expenses.

Different models of potato chip dryers exhibit significant variance in energy efficiency. Some machines can dry a batch of chips using about 5 kilowatt-hours (kWh), while others may consume over 15 kWh for the same amount. This discrepancy can make a big difference over time. If a business operates daily, the choice of a dryer impacts monthly energy bills. This is crucial for small snack businesses with tight profit margins.

It's also worth mentioning that the quality of drying isn't always perfect. Oversights can happen, leading to uneven texture or flavor. Maintaining consistent temperature and airflow requires attention. Machines that promise speed often compromise energy efficiency. Users must weigh the benefits of quick drying against the hidden costs of energy consumption and potential product quality. Energy-efficient choices are not only better for the planet but also for the bottom line.

The potato chips drying technology has seen significant shifts recently. Companies focus on improving the efficiency of drying machines. They're exploring new materials and methods that promise better results. Some machines now use advanced air circulation techniques for even drying. This can reduce energy consumption significantly.

However, not all innovations are foolproof. Certain methods may lead to uneven results. There are still challenges in achieving the perfect crispiness. For instance, some machines over-dry chips, making them brittle. Others might not remove enough moisture, leaving a chewy texture. Manufacturers are working to refine these technologies to address such issues.

Consumer preferences are evolving, too. Many now seek healthier snacks. As a result, manufacturers are developing dehydrators that retain more nutrients. They are also experimenting with natural seasonings. Despite these advancements, finding the perfect machine remains tricky. It's an ongoing journey, filled with experimentation and learning.

| Model | Drying Capacity (kg/hr) | Energy Consumption (kW) | Temperature Range (°C) | Material Quality | Price ($) |

|---|---|---|---|---|---|

| Model A | 50 | 15 | 50-90 | Stainless Steel | 2000 |

| Model B | 70 | 18 | 40-85 | Aluminum | 2500 |

| Model C | 60 | 12 | 45-80 | Plastic | 1800 |

| Model D | 80 | 20 | 50-95 | Stainless Steel | 3000 |