Choosing the right Potato Blanching Machine can greatly enhance food production efficiency. Blanching is a crucial step in preparing potatoes for freezing or further cooking. It not only preserves color and flavor but also helps in maintaining nutritional quality.

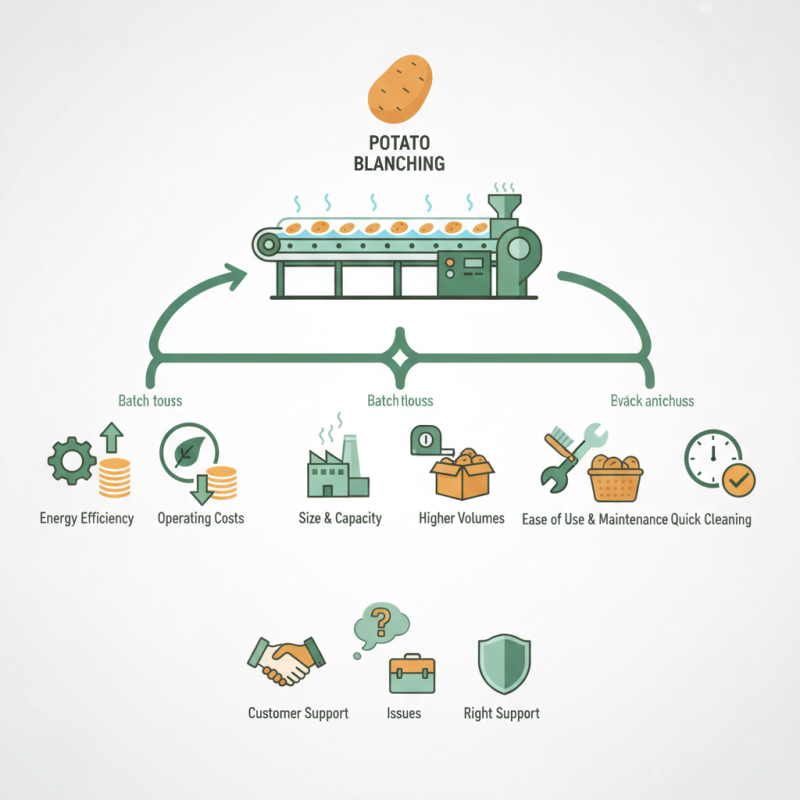

When selecting a Potato Blanching Machine, consider the size and capacity. A larger machine may handle higher volumes, but it requires more space. Think about the energy efficiency as well. High operating costs can affect your bottom line.

Another key factor is ease of use and maintenance. Complicated machinery can lead to wasted time and frustrated operators. Look for models that allow for quick cleaning. This keeps production running smoothly. Keep in mind the importance of customer support from manufacturers. No machine is perfect, and sometimes issues arise. The right support can make a big difference.

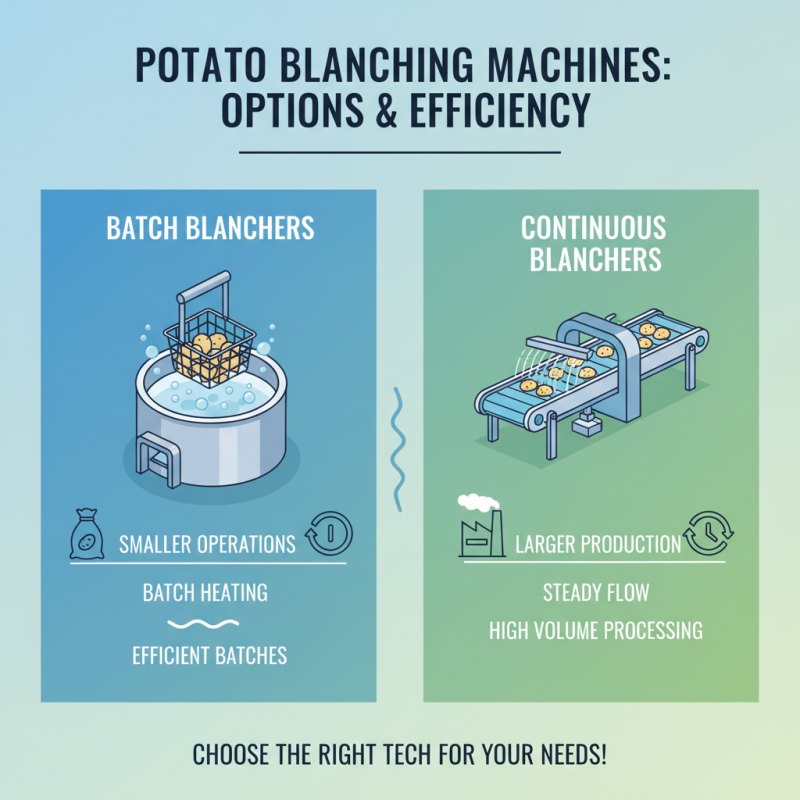

When exploring potato blanching machines, it’s crucial to understand the options available. There are batch blanchers and continuous blanchers. Batch blanchers are designed for smaller operations. They heat water in batches to blanch potatoes efficiently. Continuous blanchers, on the other hand, offer a steady flow of processing. This is ideal for larger-scale production.

Another type to consider is the steam blanching machine. Steam blanching is gentle and retains flavor and color. Some machines offer both steam and water options, providing flexibility. It is essential to evaluate the capacity of each machine. Smaller models may suit local businesses, while larger models benefit industrial settings.

Consider the energy efficiency of each type too. High-efficiency models may cost more upfront but save long-term. It's easy to overlook maintenance needs. Proper upkeep is vital for performance and longevity. The choice ultimately depends on your production needs and budget constraints. Reflecting on these aspects can lead to a better investment.

When choosing a potato blanching machine, key features should dictate your decision. The capacity of the machine matters greatly. A report from the Food Processing Industry estimates that machines with a capacity of 500 kg per hour can significantly enhance productivity. However, if you're a small business, a machine suited for 100 kg per hour might still meet your needs.

Temperature control is essential. According to research, precise temperature regulation can enhance the quality of the final product. Machines that maintain a temperature range of 85-90°C typically yield better results. Moreover, the type of heating method also impacts efficiency. Steam blanchers heat potatoes evenly, reducing cooking time. In contrast, water blanchers may lead to nutrient loss.

Another consideration is energy consumption. Efficient machines can decrease operational costs by up to 30%. It's worth noting that some machines lack transparency in energy ratings. This ambiguity can lead to unexpected expenses. Lastly, ease of cleaning should not be overlooked. Machines that enable quick disassembly can save time and labor. Ignoring this may result in inefficient operations.

When choosing a potato blanching machine, size is critical. Consider how much space you have. It directly impacts your efficiency. Smaller machines might save space but can limit your output. Larger machines occupy more space but handle bigger batches. Think about your daily needs.

Tips: Measure the area where you’ll place the machine. Ensure there's room for ventilation. This might seem trivial, but it can save headaches later.

Evaluate the volume of potatoes you usually blanch. If you're processing small amounts, a compact model works fine. However, for larger operations, you’ll need a robust machine. Balancing size with productivity is essential. Make a list of your requirements before shopping. Don't rush this process, as it leads to mistakes.

When choosing a potato blanching machine, several popular brands stand out. Each has unique features that cater to different needs. Some machines use steam, while others rely on hot water. The method you choose can impact the final product. For large-scale operations, consider machines with higher capacity. They can save time and labor.

Tips: Always check the energy efficiency of the machine. A more efficient machine can reduce operational costs. Also, read user reviews to understand common issues or advantages.

Different machines come with varied price points. Higher prices often mean better durability and advanced technology. However, not all costly machines guarantee superior performance. It's essential to weigh features against your budget.

Tips: Look into warranty options. A good warranty can save hefty repair costs later. Don’t overlook the size and space of the machine. Ensure it fits your kitchen layout perfectly.

Maintaining your potato blanching machine is essential for optimal performance. A well-cared machine can last longer, ensuring consistent results in your kitchen or factory. Regular maintenance involves simple tasks that can prevent major issues down the road.

Start by cleaning the machine after each use. Residue buildup can lead to malfunctions. Use warm, soapy water to wipe surfaces. Pay attention to hard-to-reach areas. Often, these spots are neglected but crucial for hygiene and machine health. Remember, it’s the small details that matter.

Another critical aspect is checking for wear and tear. Inspect the seals and hoses regularly. If you notice any cracks, replace them immediately. Ignoring such details can lead to costly repairs later. Don't hesitate to ask for help if you're unsure about any maintenance processes. It's better to seek assistance than to risk damaging the equipment.

Taking these easy steps will help extend the lifespan of your blanching machine. Set reminders for regular check-ups. Over time, you will develop a routine that will keep your equipment in the best shape it can be.