When it comes to making the perfect fries, the right tools can make a significant difference. A Cut Potatoes Into Fries Machine is essential for anyone serious about achieving that ideal fry texture. This machine simplifies a once tedious process, ensuring uniformity in size. Uniform fries cook evenly, resulting in a consistent taste.

However, not every machine is created equal. Some may leave you with jagged cuts or uneven shapes. Investing in a high-quality model is key, yet it requires thoughtful research. Features like adjustable blade thickness can enhance your frying experience, allowing for customization based on preference.

Fries are a beloved snack, but mistakes can happen. Overcooking or too much oil can ruin them. The Cut Potatoes Into Fries Machine should aid, not hinder your culinary efforts. This machine can streamline your kitchen workflow while helping you learn through trial and error. Embracing imperfections can lead to better mastery over time.

When it comes to cutting potatoes into fries, various machines cater to different needs. Manual cutters are simple and versatile. They require minimal maintenance and are cost-effective. However, using these machines can be tiring for large batches. Hand-cut fries have a rustic appeal, yet uniformity may be difficult to achieve.

On the other hand, electric fry cutters are more efficient. They can quickly process large quantities of potatoes. This speed is great for restaurants or food trucks. Yet, these machines can be bulky and difficult to store. Inconsistent cuts may still happen if the user isn’t skilled. Knowing how to adjust the settings is crucial.

For those who prioritize precision, industrial slicers are available. These machines offer fine control over fry thickness. They can be quite expensive and require training. Even with advanced equipment, overcooked or uneven fries can be a problem. Users should continuously evaluate their processes for improvement. Ultimately, the choice of machine relies on specific needs and preferences.

| Type of Machine | Cutting Size Options | Material | Cleaning Method | Estimated Price Range |

|---|---|---|---|---|

| Manual Potato Cutter | 1/4", 1/2" | Stainless Steel / Plastic | Hand Wash | $30 - $100 |

| Electric French Fry Cutter | 3/8", 1/4", 1/2" | Stainless Steel | Dishwasher Safe | $150 - $300 |

| Commercial French Fry Cutter | 1/4", 1/2" | Aluminum | Easy Clean | $400 - $800 |

| Countertop Fry Cutter | 1/4", 3/8" | Stainless Steel | Dishwasher Safe | $200 - $500 |

| Heavy-Duty Potato Processor | 1/4", 1/2" | Stainless Steel | Easy Clean | $600 - $1200 |

When choosing a potato fry cutting machine, there are essential features to consider. Size is crucial; a compact machine fits smaller kitchens. Capacity matters too. Look for a model that can handle your demand. A machine with adjustable cutting thickness offers versatility. Perfect fries can vary from thin shoestring to thick steak styles.

Ease of use contributes to efficiency. A design that simplifies the loading process saves time. Check for sturdy materials. Durability ensures longevity, even under heavy use. Sharp blades enhance performance, resulting in clean cuts. Regular maintenance may be required to keep blades effective.

Pay attention to safety features as well. Guards and locking mechanisms are important to prevent accidents. Some machines may not include these. Inner workings can become malfunctioning without proper care. Reflect on your specific needs. What size and style of fries do you prefer? Consider these aspects to ensure you make a well-informed decision.

When cutting potatoes into fries, achieving the right thickness is vital. Industry standards recommend a thickness of 0.25 to 0.5 inches. This range ensures even cooking and optimal texture. Fries cut too thick can be undercooked inside, while those too thin may burn easily.

Uniformity is another critical factor. Data shows that consistent fry sizes lead to better frying performance. A report from the Food Service Equipment Advisory states that fryers operate best with products cut within 1/16th of an inch. Discrepancies in size result in uneven cooking. Operators often face the dilemma of balancing efficiency and quality.

However, not all cutting machines meet these standards. Many encounter issues with inconsistent cutting. This can lead to a mix of fry sizes in a single batch. Customers notice when fries are not uniform. This can impact their dining experience. Careful selection of equipment is necessary. A poor cutting machine might require frequent adjustments. This could slow down the production line and affect service quality.

When looking for a fry cutting machine, high-volume production rates are essential. A good machine can cut large quantities of potatoes quickly. This efficiency saves time and labor, crucial for busy kitchens or food production facilities. Operators can focus on other tasks, enhancing overall workflow.

However, not all machines deliver perfect results. Some may struggle with uneven cuts. Fries that vary in size can cook inconsistently. This affects taste and presentation. It’s vital to choose a machine that balances speed with precision. Regular maintenance is key for consistent quality. Careful calibration ensures better results with every batch.

Investing in a reliable fry cutting machine pays off. The right choice can lead to satisfied customers. Quality fries make a lasting impression. However, it’s important to recognize that not every machine will meet expectations. Reflecting on past experiences can guide future decisions. Focus on finding one that aligns with your specific needs.

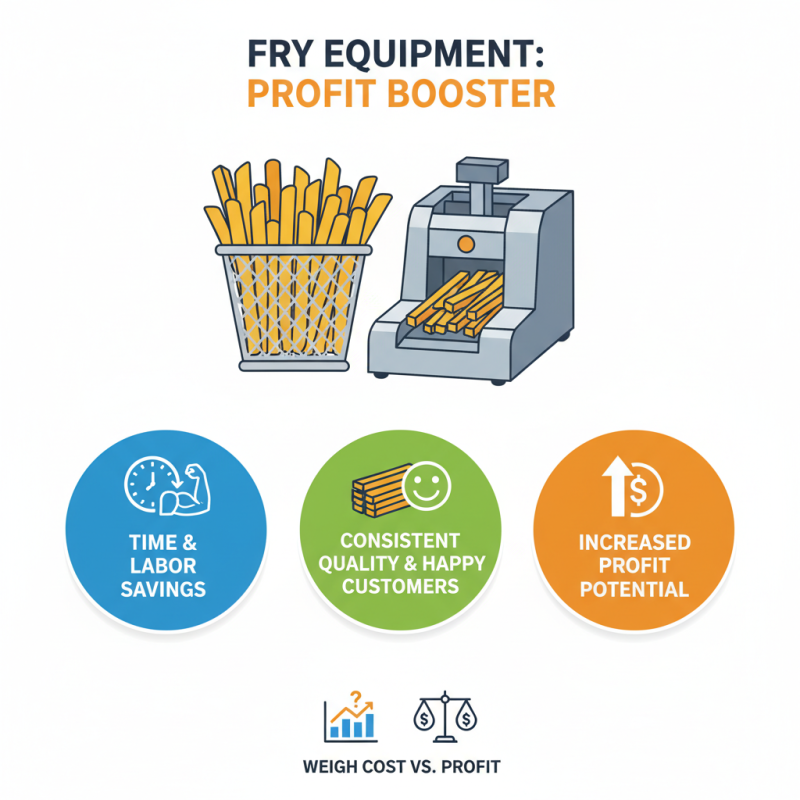

Investing in potato fry cutting equipment can deliver promising returns. For restaurants, efficiency is key. A reliable machine will save time and labor hours. It can consistently produce uniform fries, which enhances customer satisfaction. However, the initial cost can be daunting. You need to weigh the expense against the potential profit increase.

Consider maintenance costs too. Equipment may require repairs or parts replacement over time. Quality matters here; subpar machines can lead to inconsistent fry sizes. This inconsistency can frustrate both staff and customers. It's important to choose wisely. Look for models that balance cost and quality. Analyze the long-term gains against the upfront investment to see if it fits your budget.

Also, think about space. Some machines take up a lot of room. This could limit kitchen layout options. Make sure you can integrate it smoothly into your workflow. Mistakes in planning could lead to costly adjustments later. Reflect on your specific needs and choose equipment that enhances your service without overcrowding your kitchen. These are crucial considerations for any business aiming for success with their fry offerings.