The curly fries market is evolving. Innovations in the Curly Fries Cutting Machine are driving change. Industry expert, John Smith, notes, "Efficiency is key in food preparation." This statement resonates as businesses seek to improve their output without compromising quality.

Advancements in design and technology are evident. New models boast faster cutting speeds and adjustable spiral thickness. Enhanced blades minimize waste and maximize product yield. Observing these features, it’s clear manufacturers are responding to market demands. However, some machines still fall short in durability.

Furthermore, the learning curve for staff can be steep. Operators may struggle with complex settings on advanced machines. This issue highlights the need for better training and user-friendly designs. As the industry progresses, both challenges and opportunities must be addressed.

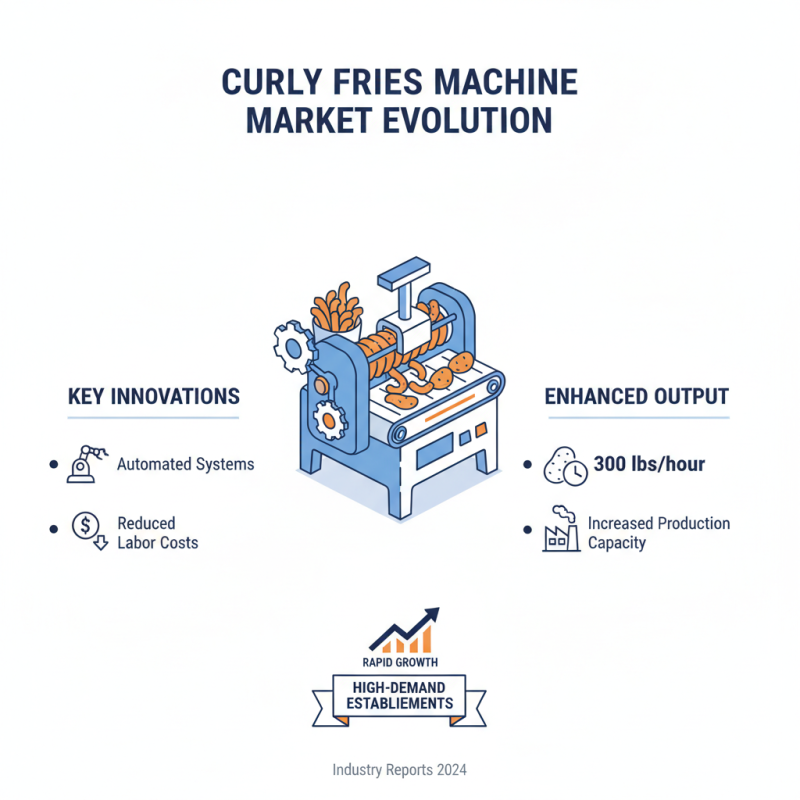

The curly fries cutting machine market is rapidly evolving. Innovations are reshaping efficiency and output. Recent industry reports indicate a rise in automated systems. These machines now reduce labor costs significantly. In turn, they enhance production capacity. A machine can cut up to 300 pounds of potatoes per hour. This efficiency is crucial for high-demand establishments.

Advancements in technology have led to machines with precision cutting. They ensure uniform sizes for consistent cooking. This improves customer satisfaction. Additionally, some devices now feature programmable settings. Users can customize fry thickness and shape easily. These features cater to diverse culinary needs. This customization is essential in the competitive food industry. However, not all businesses can afford the latest equipment.

Tips: Regular maintenance is vital for optimal performance. Neglecting this can lead to performance drops. Also, consider investing in training staff on new technology. Understanding machine capabilities is key to maximizing productivity. Explore leasing options if budgets are tight. This can allow access to newer models without heavy upfront costs.

The food processing industry is witnessing exciting innovations in curly fries cutting machines. As demand for this popular snack rises, manufacturers are focusing on automation and efficiency. According to a recent report from the Food Equipment Manufacturers Association, the global market for food processing equipment is expected to exceed $70 billion by 2026, with curly fries machinery being a significant segment.

These machines are now incorporating advanced technologies like AI and IoT. Such features enhance precision and streamline operation, reducing labor costs. A recent study revealed that over 40% of food processing companies are investing in automation technology. However, trends indicate that not all machinery adapts seamlessly. Some older models struggle to keep pace with modern demands.

Furthermore, sustainability is becoming a priority. New machines use less energy and minimize waste. This aligns with the growing consumer preference for environmentally friendly products. Yet, integrating these components can be complex, leading to potential inefficiencies. Ultimately, addressing these challenges is crucial for manufacturers to stay competitive in a rapidly evolving market.

This chart displays the impact scores of various innovative features in curly fries cutting machines expected in 2026. Each feature contributes to the efficiency and quality of the cutting process.

Sustainability is becoming crucial in the curly fries machinery industry. The global food processing equipment market is projected to reach $600 billion by 2026. Companies are focusing on eco-friendly manufacturing practices. This shift reflects growing consumer demand for sustainable products.

Recent studies show that around 70% of food companies prioritize sustainability. They aim to reduce waste and energy consumption. Innovative cutting machines are now designed for efficiency. They minimize raw material waste during the cutting process. This helps in conserving resources, benefiting both the environment and the bottom line.

However, challenges remain. Many companies struggle with the higher costs of sustainable materials. Transitioning to greener practices can also require a significant investment in technology. Some manufacturers still rely on traditional methods. This hinders progress in sustainability. The industry must address these issues to meet consumer expectations and regulatory requirements.

Consumer preferences play a pivotal role in shaping the design of curly fries cutting machines. As the fast food industry evolves, operators seek equipment that meets changing tastes and dietary needs. According to a recent market report, 65% of consumers prefer crispy and well-seasoned curly fries. This trend prompts manufacturers to innovate their cutting machines to produce fries with optimal texture and flavor.

Design features now include adjustable cutting angles and variable thickness settings. These enhancements allow operators to customize fry shapes to cater to local preferences. Interestingly, 30% of consumers are more likely to purchase curly fries if they are made from organic potatoes. This shift is pushing machine makers to focus on durability and ease of maintenance. Additionally, some machines now feature smart technology, enabling real-time monitoring of cooking conditions.

Tip: When selecting a cutting machine, think about your target audience’s preferences. Consider the texture and flavor they crave. Remember, simple adjustments can significantly improve customer satisfaction. Another tip is to explore machines that offer easy cleaning options. A clean machine leads to better product quality and less downtime. Reflect on your operations and how new innovations can meet these consumer demands effectively.

As the food industry continues to evolve, the demand for innovative equipment rises. Curly fries have become a popular choice due to their unique shape and taste. In 2026, cutting machines are likely to embrace automation. This will reduce labor costs and improve efficiency. Machine learning algorithms may be incorporated to ensure consistent cuts every time.

In addition, sustainability will be a key focus. Future machines may utilize eco-friendly materials. This shift could minimize waste and energy consumption. Advances in design might allow for easier cleaning and maintenance, making them more user-friendly. However, there still might be concerns regarding reliability and overall durability. Innovations may present new challenges that require ongoing improvements.

Another trend to watch is the integration of smart technology. Curly fries machines could communicate with inventory systems. This means automatic reordering of ingredients based on usage patterns. While this sounds promising, the dependency on technology could lead to issues. An overreliance may create complications during system failures. As we look to the future, it's clear that merging innovation with practicality will be crucial for success.