In the world of snack foods, few items boast the universal appeal of potato chips. Choosing the right Potato Chips Cutting Machine is crucial for producing uniform, delicious chips. Renowned food technology expert, Dr. Emily Thompson, once said, "Precision in cutting can enhance the flavor and texture of potato chips." This insightful remark underscores the importance of quality in the potato chip production process.

Selecting an effective Potato Chips Cutting Machine may seem simple. However, the market is flooded with various options that boast different features. Many machines promise high efficiency and perfect cuts, but not all deliver results. It’s essential to consider factors such as blade sharpness, ease of use, and durability. A machine that doesn't meet these criteria can lead to waste and unsatisfactory products.

Investing in a reliable Potato Chips Cutting Machine is vital for success in the snack industry. The stakes are high, and consumers demand quality. Therefore, a careful evaluation of available machines will make all the difference. This guide aims to address common pitfalls and highlight what features to look for. With informed choices, anyone can excel in the art of crafting delicious potato chips.

In 2026, potato chip cutting machines are seeing exciting trends. One notable innovation is the use of smart technology. These machines can now monitor cutting thickness automatically. This means getting perfectly sliced chips every time. Imagine reducing waste and optimizing production at the same time.

Another key development is energy efficiency. Some machines now utilize advanced motors that consume less power. This aspect speaks to sustainability. However, not every product on the market achieves this balance. It's crucial for buyers to research their options properly.

The evolving designs are also noteworthy. Many machines are now more user-friendly. They feature intuitive controls that minimize operational errors. Yet, some users still report frustrations with setup and maintenance. Reflecting on these issues can lead to better choices in the long run. Embracing these innovations and acknowledging their shortcomings is part of the journey in the potato chip industry.

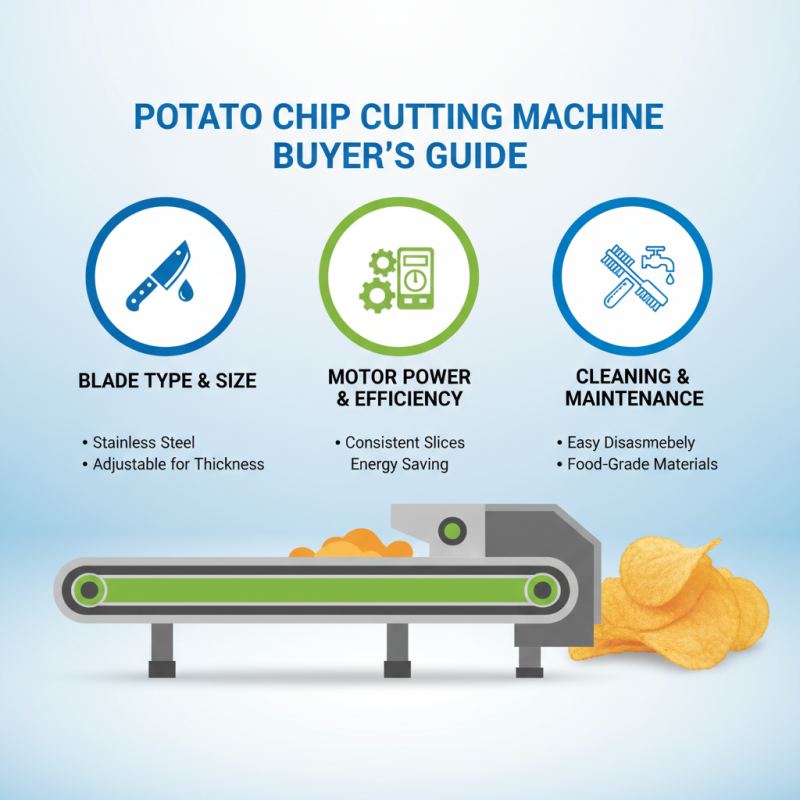

When selecting a potato chips cutting machine, several key features should guide your decision. First, consider the blade type and size. A sharp, stainless steel blade ensures clean cuts, which affect the final product's texture. Look for adjustable blade options to achieve various chip thicknesses, as consumer preference can vary greatly.

Another critical aspect is the machine's capacity. Some models handle larger volumes, making them suitable for commercial use. According to a recent industry report, demand for potato chips is projected to grow by 5% annually. A machine that can keep up with this demand is essential for business growth.

Tips: Regular maintenance is crucial. Keep blades sharp and clean to extend the machine's lifespan. Also, check for ease of cleaning; a complicated machine can hinder your production schedule. Consider noise levels as well. A quieter machine can improve the working environment, especially in small spaces. Evaluate your needs carefully to ensure the machine you choose delivers consistent results.

When selecting a potato chips cutter, understanding the different brands and models is crucial. A recent study indicated that there is a 25% increase in demand for automation in food processing equipment. This trend highlights the need for efficient potato chip cutting machines. Many models vary in blade designs, operating speeds, and material durability, affecting performance and quality.

Top models often feature stainless steel blades. They provide longevity and easy maintenance. However, some users report that the cutting precision can vary across brands. A comparative review of user experiences shows about 30% of buyers face inconsistent results in thickness. This inconsistency can lead to uneven cooking times, impacting the end product's taste and texture.

Additionally, slice capacity is an important factor. Machines with higher throughput can process between 200-300 pounds of potatoes per hour. However, discussing limitations is vital. Some users find that smaller machines struggle with larger potato sizes. This can lead to blockages and additional downtime. It’s important to reflect on these aspects when considering the right cutter for your needs.

When considering potato chips cutting machines, efficiency is crucial. A recent industry report emphasized that an efficient machine can boost production rates by up to 30%. This is significant for manufacturers aiming to meet rising consumer demand. Notably, operators often report less waste with high-quality cutting precision. Many cutting machines achieve tolerance levels of around 1-2 mm, which is vital for uniform chip size.

Productivity metrics are similarly important. Machines that operate continuously for over 10 hours tend to perform better in high-demand situations. However, frequent downtime for maintenance can negate these advantages. Some operators find that understanding the maintenance needs of machines can enhance overall productivity. Balancing operational efficiency with reliable maintenance schedules is essential.

Moreover, not all machines are created equal. While some models promise high output, they may struggle with certain types of potatoes. User feedback highlights the importance of adaptability. Buyers must carefully assess their specific production needs before making a purchase. This reflects the reality of the market: finding the right machine involves trial and error.

| Model | Cutting Speed (kg/hr) | Power Consumption (kW) | Dimensions (L x W x H) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 150 | 1.5 | 120 x 60 x 80 cm | 50 | 2500 |

| Model B | 200 | 2.0 | 130 x 70 x 85 cm | 60 | 3000 |

| Model C | 175 | 1.8 | 125 x 65 x 82 cm | 55 | 2700 |

| Model D | 220 | 2.2 | 140 x 75 x 90 cm | 70 | 3500 |

| Model E | 190 | 1.9 | 135 x 68 x 88 cm | 58 | 2800 |

Maintaining a potato chips cutting machine is crucial for its longevity. Cleaning the machine after each use is essential. Food particles can accumulate and cause rust. Regularly check for dull blades. Dull blades can lead to uneven cuts. This affects the quality of the chips.

Lubrication is another key aspect. Apply the appropriate lubricant to moving parts. This reduces friction and wear. Yet, users often forget this step. It is easy to overlook during busy production times. This can lead to machine failure down the line.

Lastly, storing the cutter properly is vital. If moisture gets in, it can damage components. Keep the machine in a dry area. A simple cover can protect it from dust and debris. Many users neglect this detail. Over time, improper storage can lead to increased repair costs. Reflect on your maintenance routine and make adjustments where necessary.

This chart illustrates key performance metrics for potato chips cutting machines, including cutting speed, efficiency, maintenance frequency, and durability. These attributes are essential for assessing the quality and longevity of potato chip cutters.